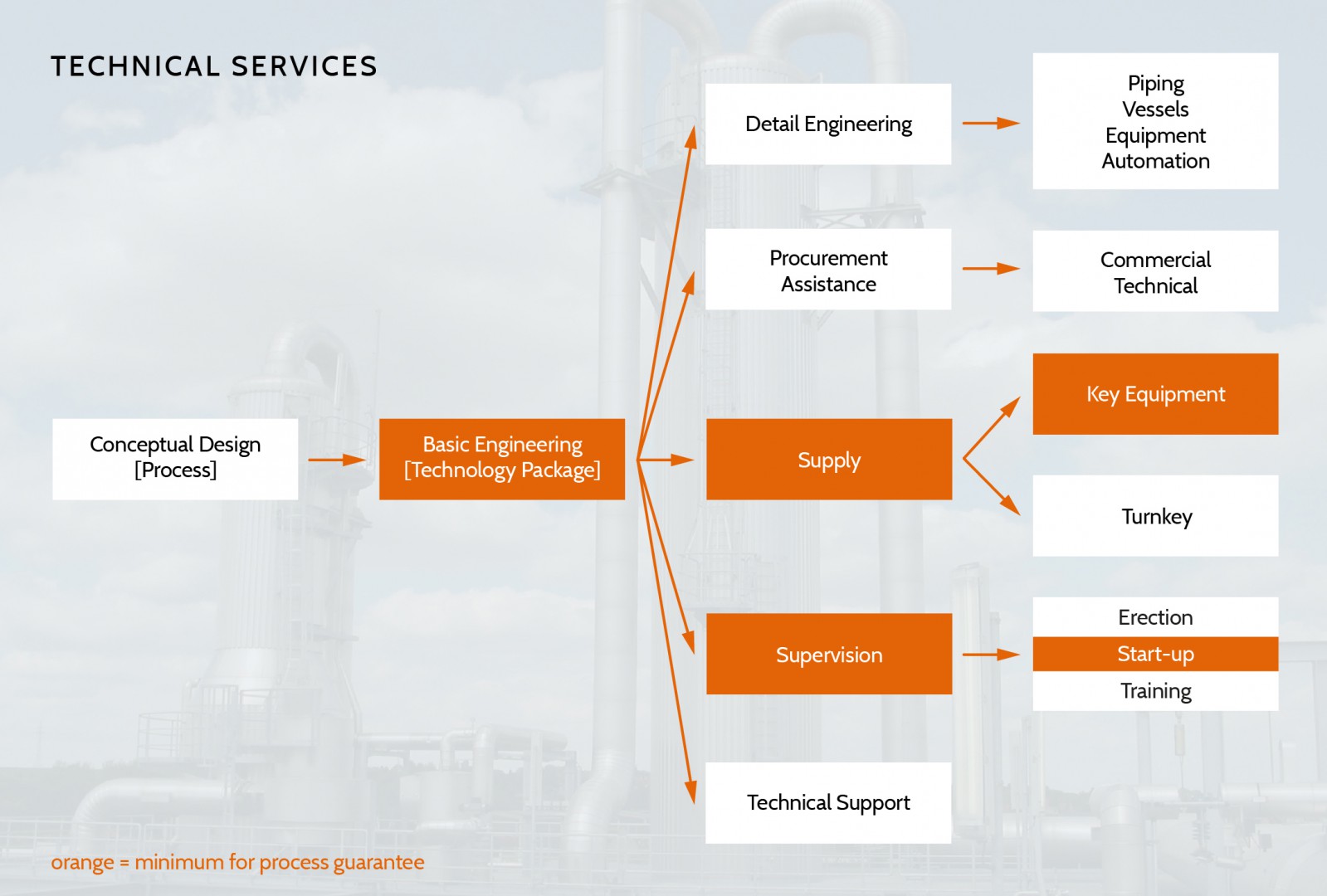

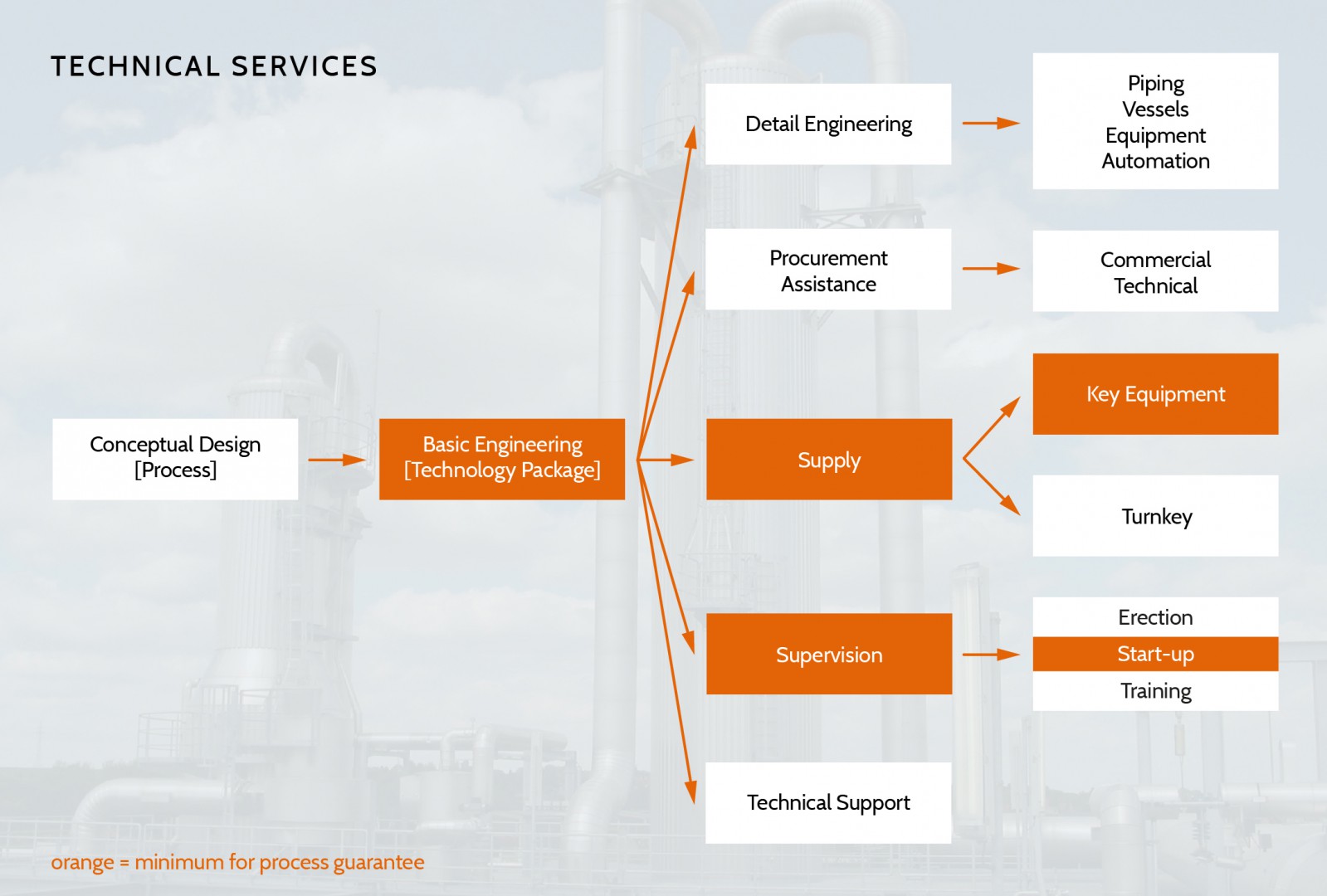

From design to start-up

Vogelbusch provides engineering documentation and various types of service packages to assist in project implementation. Coming up with the best possible solutions also includes scaling our services to your needs.

Vogelbusch provides engineering documentation and various types of service packages to assist in project implementation. Coming up with the best possible solutions also includes scaling our services to your needs.

We transfer our technologies to clients and / or help them to improve their own processes. Our engineering capabilities cover the construction and upgrading of biotechnological production systems, with services ranging from feasibility studies through to the launch of production.

Rather than start out from standard solutions we focus on your special requirements from the outset — in terms of raw materials, product quality, plant configuration and the scope of service delivery. We concentrate on getting to know your problems and coming up with the best possible solutions.

As part of conceptual design the fundamentals of your project are developed.

Starting from scratch, our studies give a basis to make an investment decision; examples are

Are more in-depth, to appropriately reflect the economic and technical framework of the project. In this preliminary stage of project realization we issue the technical process description and determine

Project studies that go into sufficient depth can also be used in obtaining approvals. For instance, they can serve as technical documentation for submissions for building permission or environmental impact assessments.

The actual scope of analysis, and thus the time taken to complete it, depends on the purpose and is evaluated in consultation with the client.

Our basic design package for technology transfer comprises the process engineering and documentation for the implementation of your plant.

Based on the conceptual design and - if necessary - validation of design data in our in-house laboratories, all relevant documents for the realization of the plant are issued

Basic design data establish the foundation for the following detail engineering of all components of the plant.

In the interest of process assurance, the supervision of performance tests during plant erection and commissioning is part of our design package.

We engineer the piping, vessels and equipment details, and the automation of the plant and integrate other systems.

Detailed piping design is carried out in accordance with the relevant European or US standards and regulations

Detailed design of tanks and vessels whether shop-made or built at construction sites includes

Design of instrumentation, control and automation systems includes the detailed specification of

More about » Process Automation

Engineering services for the system integration of third party processes are carried out during the inquiry, procurement and execution phase of the project and cover for instance

More about » Integration Engineering

In the course of procurement, we assist you both commercially and technically.

Our services are designed to facilitate your own procurement, including local supplies. We can coordinate the purchasing process and support you with

Our scope of supply services is customized, ranging from critical equipment components to full EPC contracts.

In the interest of process assurance, we assume responsibility for supplying key equipment. This is the equipment that is critical to fulfillment of the process guarantee, and includes for instance

Optionally we can supply all major parts of equipment.

We also provide custom designed technical components for our plants.

Depending on the project scale we can also offer turnkey installation of complete process units, such as

Where appropriate, units are skid-mounted to accelerate the installation process.

On site, we go along with you throughout project execution and oversee the plant start-up.

During erection of the plant our activities focus on

After certification of completion by the client, start-up supervision and acceptance testing include

We continue to work for you after plant handover.

To round off our customer service beyond initial start-up, we assist with extended supervision and personal support in order to

Take the benefit from our technical expertise for queries with your existing equipment.

We provide technical advisory services relating to the upgrade or revamp of existing plants for improvement of productivity and process economics. Let us help you to make the most of your resources, for instance

As well as process improvements for operational cost reductions such as

We analyze your process data and come up with adequate solutions that align with your manufacturing goals.